New Construction - Deep Foundation Support System

As Chicagoland sees more and more development, marginal sites see more and more construction. Usable bearing soil may only exist at levels deeper than normal. Attached or nearby structures may prevent the use of H-Piles or poured concrete foundations.

Providing only the highest quality materials and services, Atlas Restoration’s Chicago foundation construction services counts on Helical Pier® Foundation Systems, manufactured by CHANCE®, in anchoring capacities for towers and building structures sensitive to wind loads, and in bearing applications for new foundations.

Atlas Restoration’s Chicago area foundation construction experts believe that design should include professional engineering input and site specific soil information. The design for ultimate and allowable bearing or anchor loads for helical products is established only through classical geotechnical theory, supplemented by empirical data developed from field load tests.

Other applications for helical piers and micropiles in the Chicago area include foundation support for signs and light standards, slab underpinning, and column underpinning.

Chance Helical Piles Offer the Following Benefits:

- Rapid installation

- Minimal disturbance to site

- Easy installation in limited access areas

- On-site load test capability

- Immediate loading

- Installation in all weather

- Excellent strength

- No vibration

- No removal of soil

- More economical than other foundation types

- Both anchoring and bearing capabilities

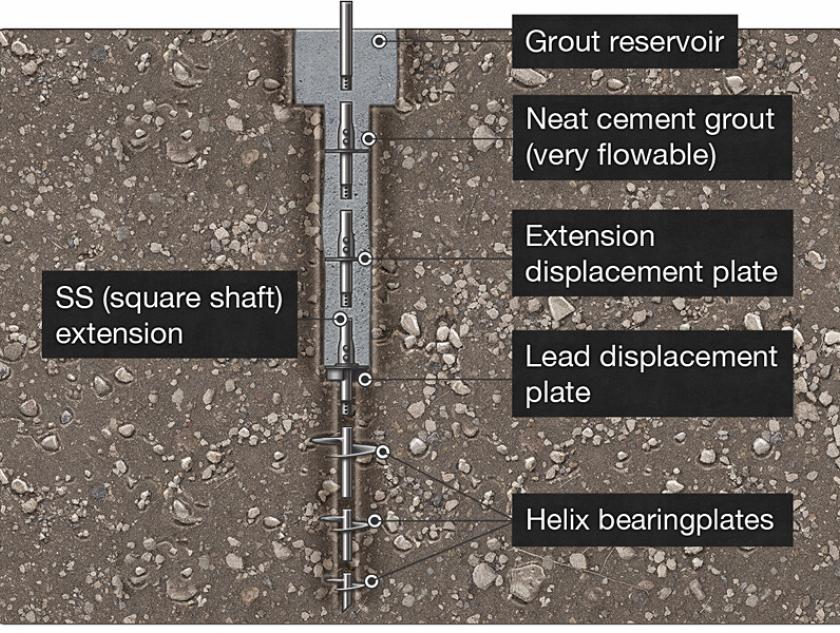

To begin our Chicago area foundation construction process, a helical anchor/pile is placed into the soil by applying torque to the shaft. The helical shape of the bearing plates creates a significant force, which continuously advances the foundation further into the soil. After the lead section with the helical plates enters the soil, a lead displacement plate and extension are placed onto the shaft. Resuming torque on the assembly advances the helical plates and pulls the displacement plate downward, forcing soil outward to create a cylindrical void around the shaft. From a reservoir at the surface, a flowable grout immediately fills the void surrounding the shaft. Additional extensions and displacement plates are added until the helical bearing plates reach the minimum depth required or competent load-bearing soil. This displacement pile system does not require removing spoils from the site.