Client: Commercial Auto Service Facility

Location: Forest Park, IL

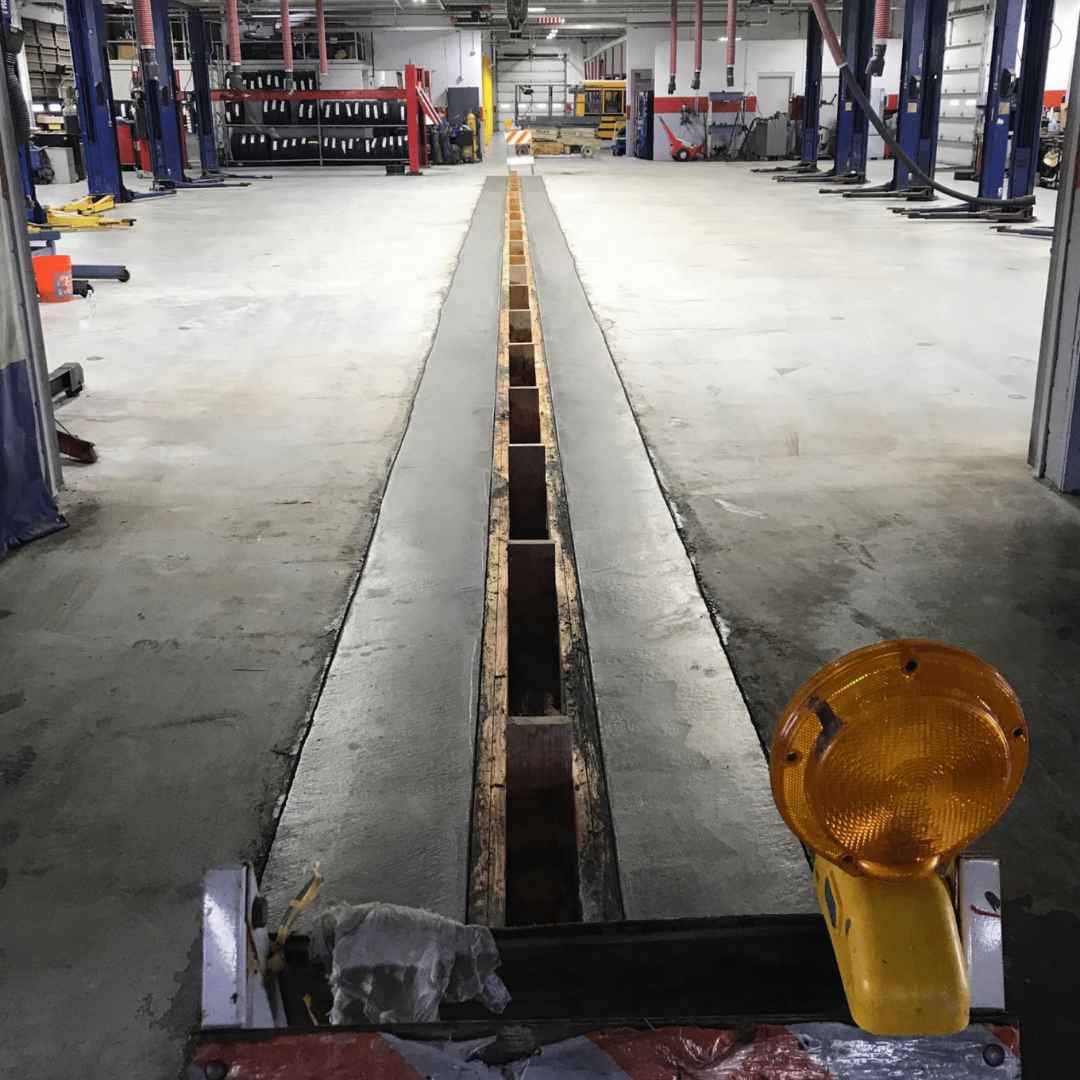

Service: Concrete Removal & Replacement, Trench Drain Installation

Completion Date: 05/03/2019

Overview

A commercial auto service facility needed to remove and replace a failing trench drain system in one of their busiest service bays. The original cast iron drain system had deteriorated over time, creating drainage issues and potential safety hazards. The goal was to provide a durable, updated drainage solution with minimal disruption to daily operations.

Challenges

The project required tight coordination and specialized planning to address several unique challenges:

- Active Facility Operations: All work had to be completed while the facility remained in use, requiring minimal disruption to staff and service.

- Full Drain System Replacement: The existing cast iron trench system was embedded in concrete and had to be completely removed and replaced.

- Tight Timeline: The project needed to be completed within five working days to allow the bay to reopen for regular use.

Solution

Atlas Restoration executed a full trench drain replacement, including concrete demolition, drain system installation, and finishing, all within the client’s time constraints.

Key steps in our approach:

Concrete Demolition & Site Prep (S1):

Roughly 90 linear feet of concrete (totaling 380 square feet) were saw cut and removed to a depth of 10 inches. All material was legally disposed of off-site.

Drain System Removal (S2):

The embedded cast iron system was removed. The exposed trench was filled with compacted CA-6 stone to ensure a stable base.

Reinforcement & Forming (S3):

Steel rebar dowels were drilled and epoxied into the surrounding slab every 18", providing structural support for the new pour. Custom formwork was built to frame the trench and provide a lip for steel grate installation.

Concrete Pour & Finish (S4):

5,000 PSI ready-mix concrete was poured and finished with a smooth trowel surface, designed to withstand vehicular traffic.

Grate Installation (S5):

Steel trench grates (1” thick x 12” wide x 3’ long) were installed and secured with industrial-grade urethane caulk for long-term sealing.

Final Walkthrough (S6):

The Atlas Restoration team conducted a final walkthrough to ensure proper installation, site cleanliness, and full scope completion. All visual differences between the original and new system were clearly documented in advance to manage expectations.

Outcome

The new trench drain system was installed on time and built to handle the daily demands of a high-traffic service area. Reinforced concrete, compacted base material, and durable steel grates provide a lasting solution with improved functionality and minimal future maintenance.

Project Highlights:

- 90 linear feet of trench drain replacement

- 380 square feet of 10" deep concrete removed and replaced

- Compacted CA-6 stone base for foundation stability

- Epoxied steel rebar reinforcement every 18"

- 5,000 PSI smooth trowel concrete finish

- Industrial steel grates sealed with MasterSeal NP-2

- Completed within a 5-day window

Why Choose Atlas Restoration?

We specialize in efficient, durable solutions for commercial drainage and concrete restoration projects. Our experienced team ensures minimal disruption, expert craftsmanship, and long-lasting results—no matter how complex the job.

Need help with trench drain or concrete repairs?

Contact us today to discuss your project.