Curling is one of the most common defects found in floors, especially in warehouses. Slabs curl upward at joints, saw-cuts and edges. This loss of sub-grade support causes slab movement as forklifts pass over the joint. Joint edges deteriorate, cracks in the slab develop and wires embedded in concrete for automatic guidance systems may break. The amount of differential movement from one side of the joint to the other is directly related to the speed of warehouse floor deterioration.

Diagnosing Curling

Movement is precisely measured at joints to assess severity of curling. Straight edges are also used to determine amount of curl. Movement greater than .015 inches is severe enough to cause deterioration three to four times as fast as normal.

Restoring sub grade support is the key to the repair.

The Process of Curl Elimination and Repair

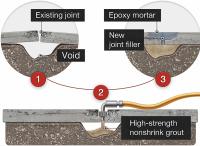

- Holes are drilled on each side of the joint where curling has occurred.

- A cementitious, non-shrink grout is pumped in under low pressure to fill voids beneath curled edges.

- Surface restoration is performed by removing the distressed concrete, reconstructing slab edges with polymer concrete and reestablishing the joint. These repairs often include grinding the surface to improve rideability and replacing damaged joint sealant material.

- Work is most commonly done at night and on weekends to avoid disruption to normal warehouse operations.