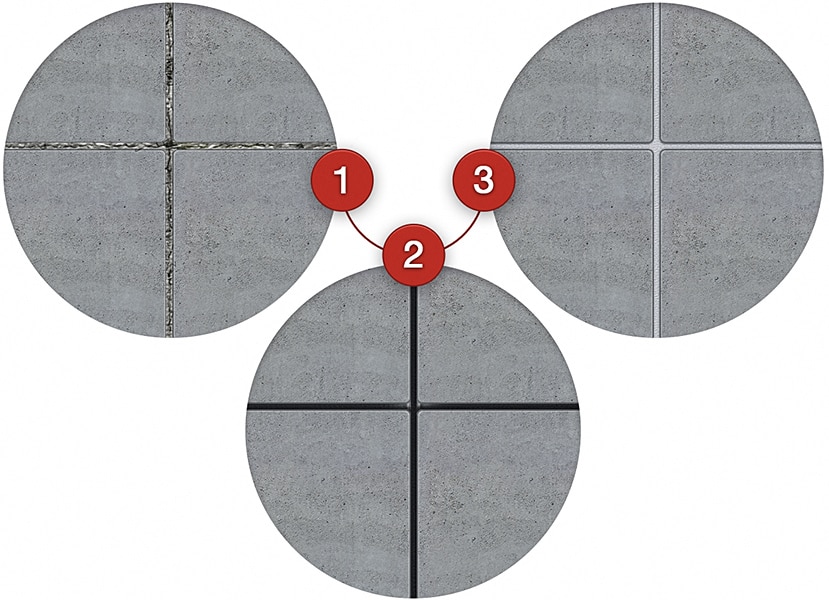

Joint edge spalling is often the result of joint movement caused by curled slab edges. As slabs deflect, due to voids under the joint, and a loaded vehicle drives on the slab, the slab drops down (or "deflects") and the vehicle wheels hit the leave slab. Another possible cause of joint edge spalling is keyed construction joints; if a keyway is too large, slab cracking above the female side of the keyway may occur.

Atlas Restoration's Repair Methods

To repair deteriorated joints, the perimeter edge of the deteriorated area is saw-cut and the unsound concrete is removed. This is usually a partial-depth repair, although in the case that a full-depth joint repair is required, the concrete will be removed to the sub-base to allow for full-depth mortar repair. For mortar reinstatement, Atlas Restoration performs armored joint repair, which utilizes a high strength epoxy mortar. The materials used in armored joint repair exhibit excellent bond strength to the substrate, minimal shrinkage/cracking and powerful abrasion resistance. Using forklifts with hard wheels (instead of pneumatic tires, which are hard on joint edges), after proper surface preparation, the epoxy binder is added to the sand aggregate and the material is placed by trowel into the blockout saw-cut area. The material is usually installed to depths of 1⁄2 inch to 2 inches, providing excellent impact and wear resistance.

After the mortar cures, the control joint is re-cut to provide crack control. The joints are then filled with an elastomeric sealant to protect the joint edges. Atlas Restoration utilizes Polyurea and epoxy joint fillers. The Polyurea materials offer a rapid set time that permits trimming of the joints within ten minutes of installation and allows for traffic within one hour.